CAPABILITIES

DOWNLOAD CAPABILITIES STATEMENT

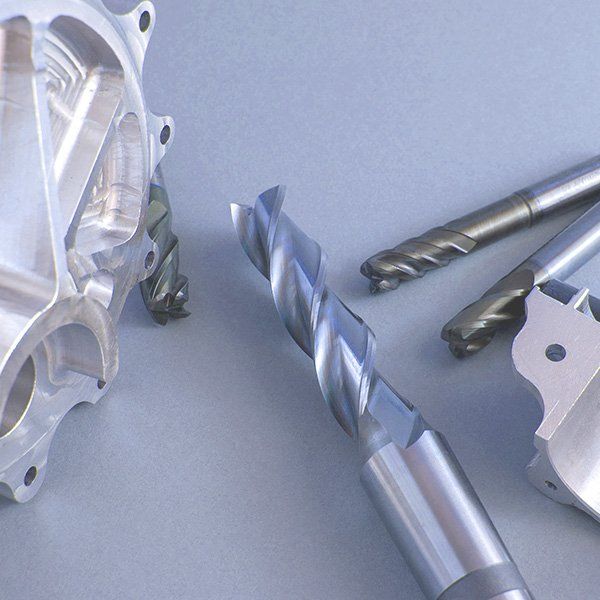

We have a comprehensive inventory of aluminum, stainless steel, mild steel, tool steel, titanium, brass, copper, PEEK, acetal, UHMW, acrylic, and many others with full traceability. We have created parts with exotic materials. Our service team works for your success, managing processes, inventory, and quality. Our team is committed to your success, from design to prototype and production. We have a customer ERP to provide live status updates. We don’t just build parts; we build relationships.

- MILLING: 2D through Full 5-axis capacity

- TURNING: Multi-Axis Dual Processing Turning

- DUAL PROCESSING: Vertically Integrated Milling and Turning

- CMM, or Coordinate Measuring Machine

- GD&T, Metrology PPAP, SPC and FAI capabilities

- Tool Load Monitoring & Tool Life Management

- CAD/CAM Design

- Reverse Engineering

- Automated | Robotic Loading Machines

- Machine Simulation & Probing

- Custom Work-holding Design and Manufacturing

- Lights out Manufacturing

- Hard Turning

- Grooving and Face Grooving

- Deep hole Drilling

- Boring

- Reaming

- Parts Cleaning

- Degreasing

- Deburring

- Tumbling

- Metal Surface Treatment

- Coating & Plating Processes

- Anodizing

- Galvanizing

- Enameling

- Electroplating

- Painting

- Chrome & Nickel Plating

- Powder Coating

- Bead Blasting

- Sand Blasting

- Polishing

- Laser Marking

- Engraving